Check Valves

Swing and Inline Piston

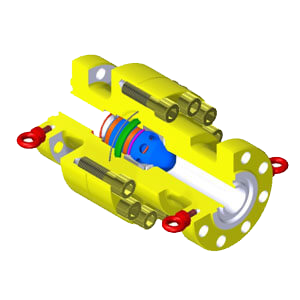

Check Valves – Piston

Pacson’s subsea Piston Check Valve is available from 1/2” to 6” and Pressures up to 17,500psi.

The valve can also be incorporated within needle and gate valves for chemical injection applications.

Product Features

- Metal to metal seat sealing with additional Polymeric secondary seat seal for bubble tight isolation on gas service and at low pressures

- No requirement for elastomers in process wetted areas

- Metal seated static body joint. Elastomer variation shown is optional

- API 17D Second Edition qualified

- 2.1/16” Non-hard face variant qualified to 10,000psi. Although API 6A Annex I only requires to 5,000psi its qualified to 7,500 psi qualified

- 2” and larger can be offered c/w hard facing for sand slurry applications

Design Benefits

- No requirement for elastomers in process wetted areas

- API 17D Second Edition qualified

- 2-1/16” Non-hard face variant qualified to 10,000psi. Although API 6A Annex I only require to 5,000psi its qualified to 7,500 psi qualified

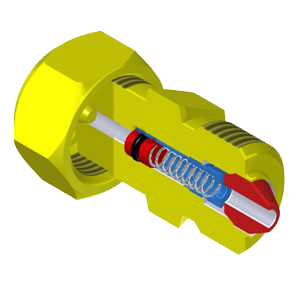

Check Valves – Bleeder Plug

Applications include Surface wellheads, valve stem sealant injection, pressure venting, etc

Available Sizes & Pressure Ratings

Materials Offered

½” NPT & L.P. up to 10,000 PSI Max WP

API 6A Type II connection up to 20,000 PSI Max WP

- 316 Stainless Steel

- Duplex UNS 31803

- Inconel UNS NO6625

- Inconel UNS NO7718

Product Features

- Utilises a metal to metal primary seat seal with elastomeric back-up for bubble tight gas and low pressure sealing

- The Pacson Bleeder Plug with API 6A Type II connection will be API 6FA fire tested by the end of 2018

- A range of Stinger Tools can be supplied to work with the Pacson Bleeder Plugs

Design Benefits

- A range of Stinger Tools can be supplied to work with the Pacson Bleeder Plugs

- Simple, established design

- Double barrier to process

- Inherently fire-safe design